MARINE & OFFSHORE EQUIPMENT

- Dredging Equipment

- Marine Deck Machinery

-

Marine Mooring Equipment

-

Marine Anchor

- AC-14 HHP Anchor

- Admiralty Anchor

- Beldt Stockless Anchor

- Bruce Anchor

- Spek Anchor

- Danforth HHP Anchor

- Delta High Holding Power Anchor

- GB11579-89 Light Weight Anchor

- Hall Anchor

- High Holding Power Mastrosov Anchor

- Hot Dip Galvanized Anchor

- Japan Stock Anchor

- JIS Stockless Anchor

- Pool Anchor

- Single Fluke Anchor

- Stainless Steel Anchor

- Stevpris MK5 Anchor

- Stingray Anchor

- US Navy Stockless Anchor

-

Marine Anchor Chain

-

Marine Shackle

- Kenter Shackle

- D Type Joining Shackle

- Pear Shaped Shackle

- Anchor Swivel Shackle Type A

- Anchor Swivel Shackle Type B

- Buoy Shackle Type A

- Buoy Shackle Type B

- C Type Detachable Connecting Link

- D Shackle

- Forelock Shackle

- Anchor Chain Swivel Group

- Straight Shackle

- Anchor Shackle

- Marine Triangle Plate

- Anchor Chain Swivel

- Anchor Chain Joining Shackle

- Anchor Chain End Shackle

- Slim Kenter Shackle

-

Chain Chaser

-

Marine Bollard

-

Marine Chock

-

Marine Fairlead

-

Marine Chain Stopper

-

Marine Mooring Reel

-

Marine Towing Bracket

-

Mooring Rope

-

Marine Towing Hook

-

Marine Shark Jaw

- Marine Fender

-

Marine Buoy

- Marine Floating Pontoon Dock

-

Marine Anchor

- Aquaculture Equipment

- Marine Outfitting Equipment

- Marine Propulsion System

-

Marine Painting

-

Marine Auxiliary Machinery

- Marine Air Compressor

- Marine Air Receiver

- Marine Sewage Treatment Plant

-

Marine Diesel Generator Set

- Marine Oil Water Separator

- Ballast Water Management System

- Marine Hydrophore

- Marine Calorifier

- Seawater Desalination Plant

-

Marine Oil Separator

- Marine Fuel Oil Supply Unit

- Marine Heat Exchanger

-

Marine Hot Well Unit

-

Marine Incinerator

-

Marine Boiler

-

Marine Valve

- JIS Marine Valve

- DIN Marine Valve

- ANSI Marine Valve

- GB Marine Valve

- CB Marine Valve

- CBM Marine Valve

-

Marine Gate Valve

-

Marine Globe Valve

-

Marine Angle Globe Valve

-

Marine SDNR Valve

-

Marine Angle SDNR Valve

-

Marine Check Valve

-

Marine Storm Valve

-

Marine Butterfly Valve

-

Marine Quick Closing Valve

-

Marine Fire Valve

-

Marine Self Closing Valve

- Marine Valve Accessories

-

Marine Pump

- Marine Centrifugal Pump

- Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine External Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Domestic Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

- Marine Pump Parts

- Marine Life-saving Equipment

- Fire-fighting Equipment

- Marine Cable

- Marine Electrical Equipment

- Marine HVAC

-

Labour Protection Appliance

- Marine Decorative Material

-

Marine Anode

- Marine Pipe Fitting & Flange

- Marine Instrument

- Ship Building Equipment

INDUSTRY EQUIPMENT

- Hoisting Equipment

- Welding Machine & Material

-

Cutting Machine

- Container Securing Fitting

- Link Chain

- Container & Storage Equipment

-

Diesel Generator Set

- Other Equipment and Tools

- Petrochemical Equipment

- Fiber Reinforced Plastics

- Polymer Materials

- Environmental Protection Series

- Geo-products and Building Materials

- Metal Mesh

- Steel Grating

-

Earthwork Teeth

-

Turnbuckle

STOCK LIST

Contacts

Tel:+86-23-67956606

Tel:+86-23-67956606

FAX:+86-23-67956622

FAX:+86-23-67956622

Email:manager@cqhisea.com

Email:manager@cqhisea.com

Working Time: 9:00--17:00

Working Day: Monday to Friday Website: www.cqhisea.com

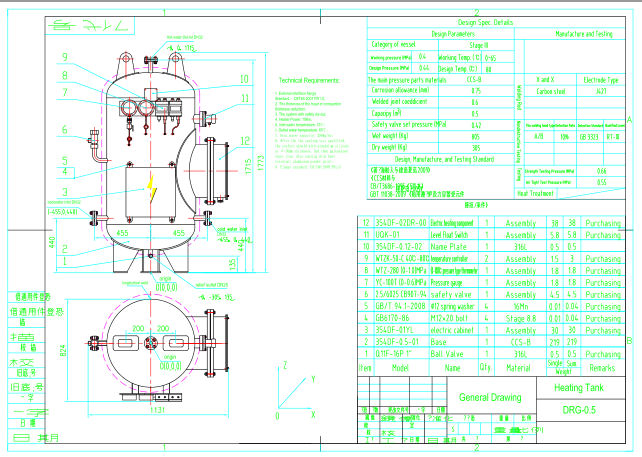

DRG-0.5 Calorifier Tank

DRG-0.5 Calorifier Tank

1. DRG-0.5 Calorifier Tank Application

This series calorifier tank is suitable for heating fresh water on the ship or platform, heated fresh water for crew use.

2. DRG-0.5 Calorifier Tank Technical Datas

Model: DRG-0.5

Capacity(m3): 0.5

Working pressure (MPa): 0.4(60℃)

Design pressure(MPa): 0.44

Test pressure(MPa): 0.66

Safety valve open pressure(MPa): 0.42

Water inlet temperature(℃): 15

Water outlet temperature (℃): 65

Working temperature(℃): 0~65

Design temperature(℃): 80

Heated water capacity(kg/h): 720

Electrical heating power(kW): 48

The thickness of the external thermal layer(mm): 40

The thickness of outer galvanized sheet steel(mm): 0.7

Electricity AC380、50Hz、3φ/AC440V、60Hz、3φ

3. DRG-0.5 Calorifier Tank Care and maintenance

(1) The WTZK-50-C marine pressure type temperature controller should be installed on instrument panel vertically. It is strictly forbidden to stir with hands or tools. The Temperature detection layer should be immersed in water completely. Don’t impact and compress the capillary. The bending radius can't be shorter than 50mm. It is needed to fix the capillary with clip every 300mm to ensure the safety.

(2) During the using of electric heater, if there is scale or carbon deposition on pipe, it is needed to use after cleaning so as to avoid affecting the service life and efficiency of electric element. If it is without of using for a long time, When the cold insulation resistance is lower than 1MΩ, it can be cured in the oven of 200℃ until returning to normal.

(3) Remove and clean the water tank regularly. After cleaning and brushing the inner wall, determine whether repaint according to flaking condition of painting. Repaint the out surface with anti-corrosive paint, meanwhile, replace wearing parts. After the spare parts are dry, reassemble it.

4. DRG-0.5 Calorifier Tank General Drawing

.jpg)