MARINE & OFFSHORE EQUIPMENT

- Dredging Equipment

- Marine Deck Machinery

-

Marine Mooring Equipment

-

Marine Anchor

- AC-14 HHP Anchor

- Admiralty Anchor

- Beldt Stockless Anchor

- Bruce Anchor

- Spek Anchor

- Danforth HHP Anchor

- Delta High Holding Power Anchor

- GB11579-89 Light Weight Anchor

- Hall Anchor

- High Holding Power Mastrosov Anchor

- Hot Dip Galvanized Anchor

- Japan Stock Anchor

- JIS Stockless Anchor

- Pool Anchor

- Single Fluke Anchor

- Stainless Steel Anchor

- Stevpris MK5 Anchor

- Stingray Anchor

- US Navy Stockless Anchor

-

Marine Anchor Chain

-

Marine Shackle

- Kenter Shackle

- D Type Joining Shackle

- Pear Shaped Shackle

- Anchor Swivel Shackle Type A

- Anchor Swivel Shackle Type B

- Buoy Shackle Type A

- Buoy Shackle Type B

- C Type Detachable Connecting Link

- D Shackle

- Forelock Shackle

- Anchor Chain Swivel Group

- Straight Shackle

- Anchor Shackle

- Marine Triangle Plate

- Anchor Chain Swivel

- Anchor Chain Joining Shackle

- Anchor Chain End Shackle

- Slim Kenter Shackle

-

Chain Chaser

-

Marine Bollard

-

Marine Chock

-

Marine Fairlead

-

Marine Chain Stopper

-

Marine Mooring Reel

-

Marine Towing Bracket

-

Mooring Rope

-

Marine Towing Hook

-

Marine Shark Jaw

- Marine Fender

-

Marine Buoy

- Marine Floating Pontoon Dock

-

Marine Anchor

- Aquaculture Equipment

- Marine Outfitting Equipment

- Marine Propulsion System

-

Marine Painting

-

Marine Auxiliary Machinery

- Marine Air Compressor

- Marine Air Receiver

- Marine Sewage Treatment Plant

-

Marine Diesel Generator Set

- Marine Oil Water Separator

- Ballast Water Management System

- Marine Hydrophore

- Marine Calorifier

- Seawater Desalination Plant

-

Marine Oil Separator

- Marine Fuel Oil Supply Unit

- Marine Heat Exchanger

-

Marine Hot Well Unit

-

Marine Incinerator

-

Marine Boiler

-

Marine Valve

- JIS Marine Valve

- DIN Marine Valve

- ANSI Marine Valve

- GB Marine Valve

- CB Marine Valve

- CBM Marine Valve

-

Marine Gate Valve

-

Marine Globe Valve

-

Marine Angle Globe Valve

-

Marine SDNR Valve

-

Marine Angle SDNR Valve

-

Marine Check Valve

-

Marine Storm Valve

-

Marine Butterfly Valve

-

Marine Quick Closing Valve

-

Marine Fire Valve

-

Marine Self Closing Valve

- Marine Valve Accessories

-

Marine Pump

- Marine Centrifugal Pump

- Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine External Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Domestic Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

- Marine Pump Parts

- Marine Life-saving Equipment

- Fire-fighting Equipment

- Marine Cable

- Marine Electrical Equipment

- Marine HVAC

-

Labour Protection Appliance

- Marine Decorative Material

-

Marine Anode

- Marine Pipe Fitting & Flange

- Marine Instrument

- Ship Building Equipment

INDUSTRY EQUIPMENT

- Hoisting Equipment

- Welding Machine & Material

-

Cutting Machine

- Container Securing Fitting

- Link Chain

- Container & Storage Equipment

-

Diesel Generator Set

- Other Equipment and Tools

- Petrochemical Equipment

- Fiber Reinforced Plastics

- Polymer Materials

- Environmental Protection Series

- Geo-products and Building Materials

- Metal Mesh

- Steel Grating

-

Earthwork Teeth

-

Turnbuckle

STOCK LIST

Contacts

Tel:+86-23-67956606

Tel:+86-23-67956606

FAX:+86-23-67956622

FAX:+86-23-67956622

Email:manager@cqhisea.com

Email:manager@cqhisea.com

Working Time: 9:00--17:00

Working Day: Monday to Friday Website: www.cqhisea.com

Oil Purifier Unit

Oil Purifier Unit

1. Oil Purifier Unit ApplicationThe oil purifier unit is intended for marine and land applications. It is specifically designed for cleaning of mineral oils from water and solid particles (sludge). The cleaned oil is discharged continuously, while the sludge is discharged at intervals.

The separator handles the following types of lubricating oils and low viscosity fuel oils:

Distillate (viscosity 1.5-5.5 cSt/40℃)

Marine diesel oil (viscosity l3 cSt/40℃)

Intermediate fuel oil and heavy fuel oil (viscosity 30-380 cSt/50℃)

Lubricating oil of R & O type, detergent or steam turbine.

The separator can be operated either as a purifier or as a clarifier. When operated as a purifier the separator discharges the separated water continuously.

When the oil contains only small amounts of water the separator is operated as a clarifier, discharging the water together with the solid particles.

The separator has to be installed together with devices for control of its operation.

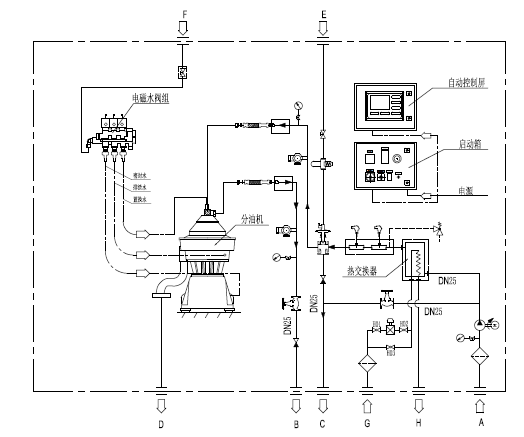

2. Oil Purifier Unit Design

The marine oil separator comprises a frame consisting of the frame lower part, the intermediate part and the frame top part with a frame hood.

The separator bowl is driven by an electric motor via a flat-belt power transmission and bowl spindle. The motor drive is equipped with a friction coupling to prevent overload.

The bowl is of disc type and hydraulically operated at sludge discharges. The hollow bowl spindle features an impeller which pumps closing water from a built-in tank to the operating system for sludge discharge.

The main inlets and outlets are shown with their connection numbers in the illustration.

3. Sludge Discharge Function of Oil Purifier Unit

Sludge is discharged through a number of ports in the bowl wall. Between discharges these ports are covered by the sliding bowl bottom, which forms an internal bottom in the separating space of the bowl. The sliding bowl bottom is pressed upwards against a sealing ring by force of the closing water underneath.

The sliding bowl bottom is operated hydraulically by means of operating water supplied to the discharge mechanism from an external freshwater line. Opening water is supplied directly to the operating system in the bowl while closing water is supplied to the built-in closing water tank, and pumped to the operating system through the bowl spindle.

The opening and closing only takes a fraction of a second, therefore the discharge volume is limited to a certain percentage of the bowl volume. This action is achieved by the closing water filling space above the upper distributor ring and pushing the sliding bowl bottom upwards. Simultaneously, the water in the chamber below the operating slide is drained off through the nozzles in the bowl body.

Bowl opening

The key event to start a sludge discharge is the downward movement of the operating slide. This is accomplished by supply of opening water to the discharge mechanism. Water is drained off through nozzles in the bowl body. The sliding bowl bottom is rapidly pressed downwards by the force from the liquid in the bowl, opening the sludge ports.

Bowl closing

After the sludge is discharged the sliding bowl bottom is immediately pressed up and the sludge ports in the bowl wall are closed.

4. Oil Purifier Unit Process Principle

5. Certificates of Oil Purifier Unit: CCS, BV.