Design and technical requirements of marine mooring winches are to comply with requirements of CCS Rules.

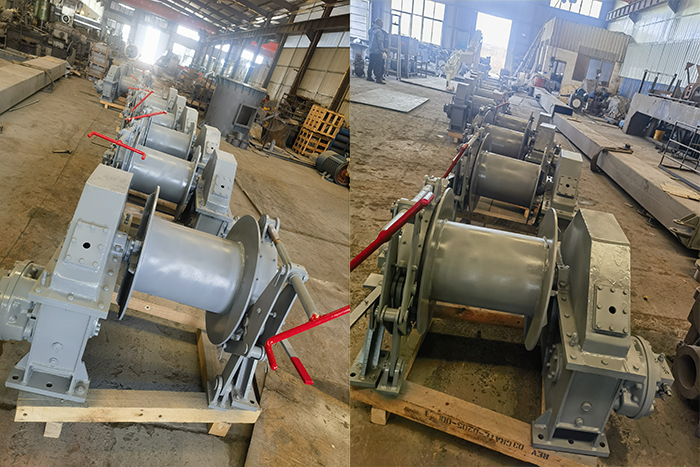

1.The mooring winch is to be able to operate, hold and store the rope on a single drum.

2.The mooring winch is to be driven by an independent prime mover and reversible.

3.The mooring winch is to be able to operate for 30 min continuously at the nominal speed with drum load.

4.The drum load shall be within 0.22 to 0.33 times the breaking strength of the design rope when operating at the corresponding nominal mooring speeds.

5.The holding load is not to be less than 80% of the design breaking load of rope.

6.The recovery load is not to be less than 50% of the drum load.

7.The rendering load is not to be more than 50% of the design breaking load of rope.

8.The mooring winch must be provided with an automatic braking system which operates when the hand-operated lever or wheel is brought to the stop or braking position or when there is no power on the winch. The brake is to be capable of stopping the drum rotating from the nominalspeed without failure when the winch is applying the drum load. The automatic braking system is to be capable of holding a static load 1.25 times the drum load. For the automatic braking device of electrical mooring winches, there is not to be any slip or damage. For hydraulic mooring winches, certain slip movement not exceeding 1 m in one minute is allowed.

The direction of motion of the operating devices is to be such that the rope is hauled in by clockwise movement at a hand lever or alternatively movement of the hand lever towards the operator and that the rope is rendered by contrary movement of the hand lever.

9.The direction of all control handles is to be clearly and permanently marked. Whatever the form of motive power, the operating device is, when under manual control, to be arranged to return to the braking or stop position automatically.

10.The drum is to be fitted with a clutch to enable it to be disengaged from the driving device and locked tightly.

11.The diameter of the drum is to comply with the following requirements:

(1) If steel wire rope is adopted, the diameter of the drum is not to be less than 16 times the design rope diameter.

(2) If polyester or polyamide rope is adopted, the diameter of the drum is not to be less than 6 times the design rope diameter.

(3) If polypropylene rope is adopted, the diameter of the drum is not to be less than 4 times the design rope diameter.

12.When all the rope is reeled on the drum, the flange is to project at least 1.5 times the rope diameter above the outermost layer.

13.Strength requirements

(1) For calculation of the stress of transmission gear and other parts under force with 100% rated torque of the prime mover, the stress obtained in respect to parts under force is not to exceed 40% of the yield limit of the material.

(2) With the maximum torque of the prime mover corresponding to the worst condition, the stress obtained in respect to parts under force is not to exceed 90% of the yield limit of the material.

(3) With the braking load being applied, the stress obtained in respect to parts under force is notto exceed 90% of the yield limit of the material.

14.The mooring winch of tanker is designed to have periodical brake test.

15.The mooring winch brake of tanker is to be the brake type with brake power to be controlled and measured.

The following is the requirement of MSC.1/Circ.1619 which is suitable for the mooring arrangement(mooring winch) designed for ships of 3,000 gross tonnage and above constructed on or after 1 January 2024,

16.The selection of winches should take into account:

(1) The availability of winches with alternative drum arrangements, including split drum arrangements, which can reduce the need for manual handling of mooring lines during mooring operations;

(2) The positioning of winch controls, including the availability of remote controls for winches to improve the line of sight and reduce operator exposure to snap-back;

(3) The availability of constant tension winches and their appropriateness for the normal operation of the ship; and

(4) Limiting noise levels to ensure proper communication during mooring operations.

17.The selection of mooring lines should take into account:

(1) The guidance on mooring restraint as per appendix A of MSC.1/Circ.1175/Rev.1;

(2) The diameter D of surfaces of mooring fittings that are in contact with the mooring line in relation to the mooring line diameter d (D/d ratio) to reduce or mitigate bend loss of strength;

(3) The compatibility of the MBLSD of mooring lines and the brake capacity of the mooring winches installed on board;

(4) The Line Design Break Force (LDBF) to be 100% to 105% of the MBLSD;

(5) The characteristics and limitations of mooring lines including material properties and environmental operating conditions anticipated during normal operation of the ship;

(6) The anticipated behaviour of the mooring line in the event of failure;

(7) The influence on stored energy and the potential for snap-back of high stiffness mooring lines caused by the use of tails; and

(8) As far as possible, but at least for lines in the same service (e.g. headlines, breast lines or springs), mooring lines of the same diameter and type (i.e. material) should be used.

18.To avoid overload on mooring winches, fittings and mooring lines, consideration should be given to select mooring winches with brake capacity of less than the ship design minimum breaking load of the mooring line or with adjustable brake capacity

19.The WLL of mooring lines should be used as user operating limiting values, not to be exceeded. The WLL is expressed as a percentage of MBLSD and should be used as a limiting value in operational mooring analyses. Steel wires have a WLL of 55% of MBLSD and all other cordage (synthetic) have a WLL of 50% of the MBLSD