Winch drum type

In addition to the distinction of quantity, there are also types of winch drums. Winch drums can be either split or undivided.

On an undivided drum outer layers of the mooring line tend to embed into lower layers when under tension which can damage the mooring line. The split drum winch was designed as a solution to this problem and is preferred by most operators. The split drum winch is composed of a tension section (sometimes called the working section), and a line storage section.

If the drum is made of one part, it serves as storage and as a drawing and pulling drum. These types of drums are only suitable for steel wire and certain synthetics. If force is applied to a synthetic hawser, it may not slip through the layers of rope below. If this does happen, the rope gets foul. Sorting the rope out again takes a lot of time.

If the drum consists of two parts. then the small part is the working drum and the other part is the storage part. The tension in a rope (with a maximum of two layers) may only be applied to the working drum.

Suppose the drum's diameter is 30 cm, and 5 windings fit next to each other in two layers. Then, the pulling drum can pull 10 metres of rope.

lf the MBL (minimum break load) of the ropes is 100%, then the holding capacity of the drum is 80%, and the pulling force is approximately 1/3 of this. This rule applies to all the drums mentioned.

1. Split drum

The split drum winch is a common drum divided by a notched flange into:

l A (line) storage section.

l A tension/working section.

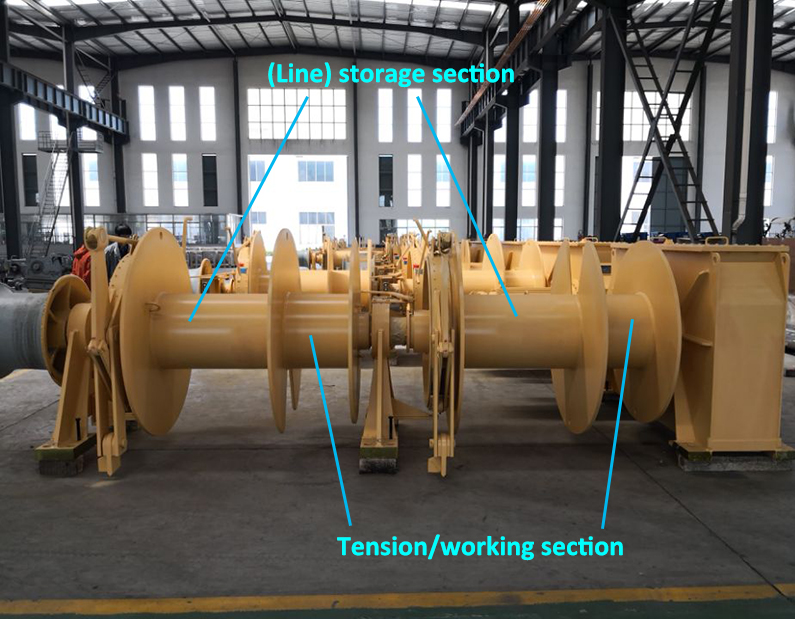

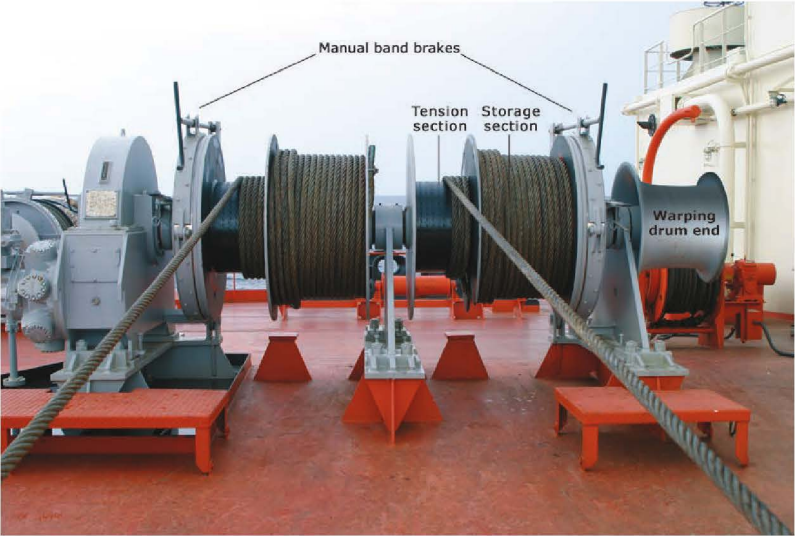

See figures 1 and 2 for examples.

The split drum winch is operated with only one layer of mooring line on the tension sectionand theoretically can maintain a constant, high brake holding power.

Figure 1: Split drum winch

Figure 2: Mooring rope(line) on the split drum winch

Advantages

l Maintains a constant brake holding capacity and heaving force because the mooring line isdesigned to run off the first layer of the tension section.

l The mooring line cannot embed into the lower layers when under tension, because there isonly a single layer of turns on the tension part of the drum. This avoids potential damage tothe mooring line.

Disadvantages

l The mooring lines need to transfer between the tension and storage drums which risksdamage to the mooring lines and to personnel.Risks can be mitigated by planning themooring operation to take into account spooling requirements, procedures, training andoperator experience.

Design requirements for drum length are included in ISO 3730. The minimum number of turns needed on the tension section of the drum may vary depending on the type of mooring line. Ship designers are recommended to allow for at least ten turns to accommodate varying mooring line types.

As a general guideline allow for the following:

l A minimum of ten turns for steel wire rope and mooring lines.

l A minimum of five to six turns for conventional fibre mooring lines.

Drums that are too wide or too small may not spool correctly.

2. Undivided drum

It is often difficult to spool and stow the mooring line satisfactorily on undivided drums. If the mooring line is not spooled properly it can be damaged when tension is applied to the system.

lt is even more important to follow the guidance on fleet angle and equipment line-up than it is for split drums.

Figure 3: Undivided drun winch

Advantages

l The mooring line does not need to transfer from section to section as is required for a splitdrum, which eliminates the potential for mooring line damage and personnel injury.

Disadvantages

l The outer layers of mooring line tend to embed into the lower layers when under tension.This is particularly an issue with synthetic mooring lines as mentioned above.

l Mechanical spooling devices on undivided drums are prone to damage.

3. Winch drums for handling SPM pick-up lines

Ships likely to trade to SPMs should be equipped to safely handle SPM pick-up lines.

Winch storage drums used to recover the SPM pick-up lines should be positioned to enable a direct straight lead with the bow fairlead and bow chain stopper without the use of pedestal rollers. This relative positioning of the tanker SPM mooring equipment in a direct lead is the safest and most efficient arrangement for handling the SPM pick-up lines. If the mooring

arrangement design does not permit a direct lead, then pedestal rollers may need to be used, but see further guidance in section 4.3.3, including limitations. Consideration may need to be given to fitting SPM mooring-specific winches in addition to any normal mooring winch and anchor windlass combinations.

Winch storage drums used to stow the SPM pick-up line should be capable of lifting at least 15 tonnes on the first layer and capable of storing 150m of 80mm diameter line. The drum flange size should be sufficient to contain this amount of line and any permanently stowedline underneath. Using warping drums to handle pick-up lines is considered unsafe and should be avoided.