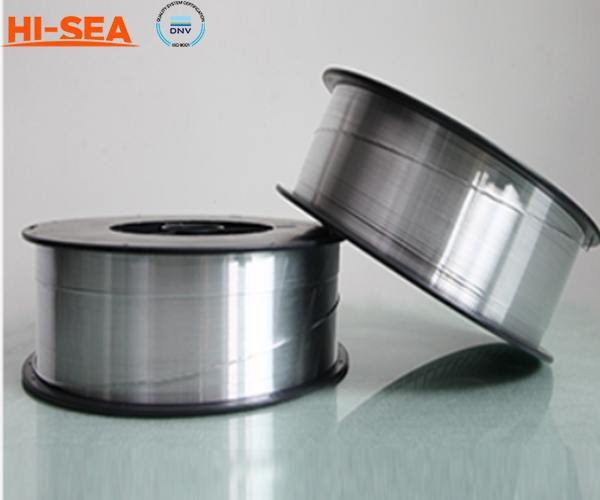

Aluminum Boat Welding Wire

Introduction:

Aluminum Boat Welding Wire" refers to the type of welding wire specifically designed for welding aluminum boats. Aluminum boats are often made from aluminum alloys due to their lightweight, corrosion-resistant properties, and welding plays a crucial role in their construction and repair.

Main Characteristics:

Alloy Compatibility: Aluminum boat welding wire is designed to match the specific alloy composition of aluminum used in boat construction. This compatibility ensures proper fusion and mechanical properties in the weld.

Oxidation Resistance: Aluminum is prone to oxidation at high temperatures, which can negatively impact weld quality. Aluminum boat welding wire often features coatings or fluxes that protect the weld area from atmospheric oxidation during the welding process.

Cleanliness: Contaminants and impurities can adversely affect the quality of aluminum welds. High-quality welding wire for boats is clean and free from contaminants that could lead to issues like porosity or weak welds.

Consistent Performance: Reliable aluminum boat welding wire delivers consistent performance in terms of arc stability, penetration, and weld appearance. This consistency is vital for producing uniform and strong welds.

Low Hydrogen Content: Hydrogen can cause cracking in aluminum welds. Quality welding wire is manufactured with low hydrogen content to minimize the risk of hydrogen-induced cracking.

Corrosion Resistance: Aluminum is often chosen for boat construction due to its corrosion-resistant properties. The welding wire should maintain the corrosion-resistant nature of the base metal in the welded joints.

Diameter Options: Different boat welding applications require different wire diameters. Aluminum boat welding wire is available in various diameters to match the thickness of the aluminum being welded.

Suitable for Welding Method: Whether it's TIG, MIG, or another welding method, aluminum boat welding wire should be suitable for the chosen welding technique.

Storage and Handling: Proper storage and careful handling of the welding wire are crucial to prevent contamination and maintain its integrity for consistent performance.

Mechanical Properties: The resulting welds should exhibit the necessary strength, ductility, and mechanical properties to ensure the structural integrity of the boat.

Product Showing: