Amorphous Metal Transformer: The New Transformer for Future Green Development

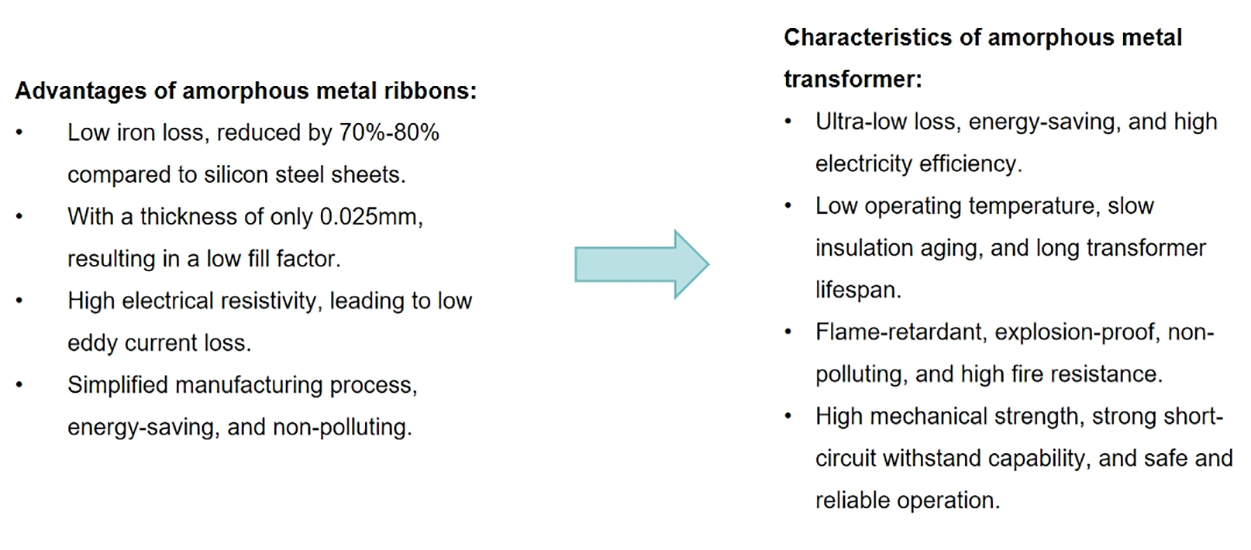

The era of using silicon steel sheets for transformer cores is gradually coming to an end. In line with green development and the practice of green energy saving, our company has introduced a new type of green transformer. This transformer uses amorphous metal ribbons for the core. The core structure is simple, has high mechanical strength, and resists high-frequency harmonics. Its iron loss is 70%-80% lower than conventional products. Compared to traditional transformers, a 2500kVA amorphous metal transformer can save 21,000 kWh of electricity per year. For 50 units, this amounts to an annual saving of 1,050,000 kWh, reducing coal consumption by 420 tons and decreasing CO2 emissions by nearly 1,050 tons.

Comparison between Amorphous Metal and Traditional Silicon Steel Sheet

1. Manufacturing Process: The manufacturing process for amorphous metal ribbons is extremely simple, consuming only a small amount of energy, making it a typical environmentally friendly material. In contrast, the manufacturing process for silicon steel sheets is complex and consumes a large amount of energy, classifying it as a high-energy consumption product.

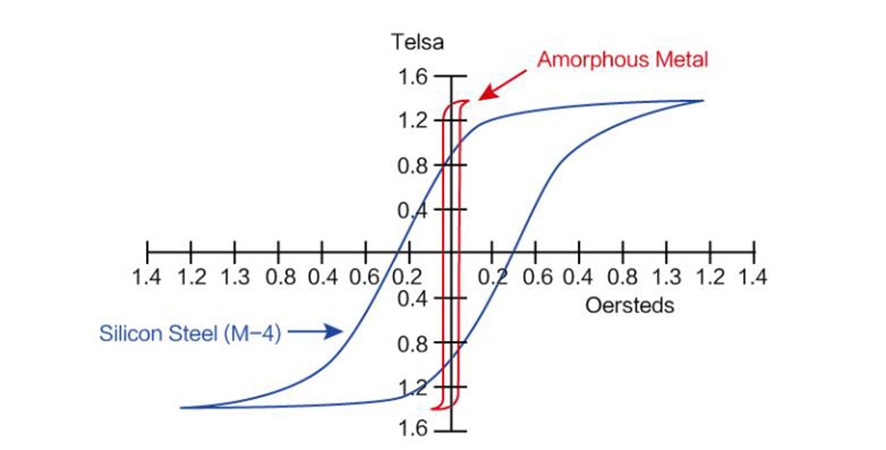

2. Comparison of Magnetization Curves: Amorphous metal have high permeability and low excitation power; low coercivity and minimal hysteresis loss; high resistivity and low eddy current loss.

The closed area enclosed by the magnetization curve in the figure represents the energy lost as heat by the magnetic material during alternating magnetic field cycles. It is clearly evident from the figure that at a magnetic flux density of approximately 1.4T, the closed area of the magnetization curve for amorphous ribbons is significantly different from that of silicon steel sheets. According to measured data, the iron loss of amorphous metal is about 10% that of silicon steel sheets. In practice, when used as transformer core material, it can reduce no-load power losses by 70% to 80%, marking a revolutionary advancement in metallurgical materials.

3. Comparison of parameters

|

|

Performance |

Amorphous metal2605SA1 |

Silicon steel |

|

Magnetic properties |

Iron loss W13/50Hz (25℃) Saturation flux density (25℃) Curie temperature |

0.1W/kg 415℃ |

0.86W/kg 745℃ |

|

Physical properties |

Density Lamination coefficient Hardness Hv Resistivity |

7.18g/cm³ >85%

860 |

7.65g/cm³ >94%

180 |

|

Dimension |

Width Thickness |

142,170,213mm |

About 950mm |

|

Other |

Annealing |

380℃~400℃ |

750℃~850℃ |

Summarize

Tel:+86-23-67956606

Tel:+86-23-67956606 Email:

Email: