MARINE & OFFSHORE EQUIPMENT

- Dredging Equipment

- Marine Deck Machinery

-

Marine Mooring Equipment

-

Marine Anchor

- AC-14 HHP Anchor

- Admiralty Anchor

- Beldt Stockless Anchor

- Bruce Anchor

- Spek Anchor

- Danforth HHP Anchor

- Delta High Holding Power Anchor

- GB11579-89 Light Weight Anchor

- Hall Anchor

- High Holding Power Mastrosov Anchor

- Hot Dip Galvanized Anchor

- Japan Stock Anchor

- JIS Stockless Anchor

- Pool Anchor

- Single Fluke Anchor

- Stainless Steel Anchor

- Stevpris MK5 Anchor

- Stingray Anchor

- US Navy Stockless Anchor

-

Marine Anchor Chain

-

Marine Shackle

- Kenter Shackle

- D Type Joining Shackle

- Pear Shaped Shackle

- Anchor Swivel Shackle Type A

- Anchor Swivel Shackle Type B

- Buoy Shackle Type A

- Buoy Shackle Type B

- C Type Detachable Connecting Link

- D Shackle

- Forelock Shackle

- Anchor Chain Swivel Group

- Straight Shackle

- Anchor Shackle

- Marine Triangle Plate

- Anchor Chain Swivel

- Anchor Chain Joining Shackle

- Anchor Chain End Shackle

- Slim Kenter Shackle

-

Chain Chaser

-

Marine Bollard

-

Marine Chock

-

Marine Fairlead

-

Marine Chain Stopper

-

Marine Mooring Reel

-

Marine Towing Bracket

-

Mooring Rope

-

Marine Towing Hook

-

Marine Shark Jaw

- Marine Fender

-

Marine Buoy

- Marine Floating Pontoon Dock

-

Marine Anchor

- Aquaculture Equipment

- Marine Outfitting Equipment

- Marine Propulsion System

-

Marine Painting

-

Marine Auxiliary Machinery

- Marine Air Compressor

- Marine Air Receiver

- Marine Sewage Treatment Plant

-

Marine Diesel Generator Set

- Marine Oil Water Separator

- Ballast Water Management System

- Marine Hydrophore

- Marine Calorifier

- Seawater Desalination Plant

-

Marine Oil Separator

- Marine Fuel Oil Supply Unit

- Marine Heat Exchanger

-

Marine Hot Well Unit

-

Marine Incinerator

-

Marine Boiler

-

Marine Valve

- JIS Marine Valve

- DIN Marine Valve

- ANSI Marine Valve

- GB Marine Valve

- CB Marine Valve

- CBM Marine Valve

-

Marine Gate Valve

-

Marine Globe Valve

-

Marine Angle Globe Valve

-

Marine SDNR Valve

-

Marine Angle SDNR Valve

-

Marine Check Valve

-

Marine Storm Valve

-

Marine Butterfly Valve

-

Marine Quick Closing Valve

-

Marine Fire Valve

-

Marine Self Closing Valve

- Marine Valve Accessories

-

Marine Pump

- Marine Centrifugal Pump

- Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine External Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Domestic Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

- Marine Pump Parts

- Marine Life-saving Equipment

- Fire-fighting Equipment

- Marine Cable

- Marine Electrical Equipment

- Marine HVAC

-

Labour Protection Appliance

- Marine Decorative Material

-

Marine Anode

- Marine Pipe Fitting & Flange

- Marine Instrument

- Ship Building Equipment

INDUSTRY EQUIPMENT

- Hoisting Equipment

- Welding Machine & Material

-

Cutting Machine

- Container Securing Fitting

- Link Chain

- Container & Storage Equipment

-

Diesel Generator Set

- Other Equipment and Tools

- Petrochemical Equipment

- Fiber Reinforced Plastics

- Polymer Materials

- Environmental Protection Series

- Geo-products and Building Materials

- Metal Mesh

- Steel Grating

-

Earthwork Teeth

-

Turnbuckle

STOCK LIST

Contacts

Tel:+86-23-67956606

Tel:+86-23-67956606

FAX:+86-23-67956622

FAX:+86-23-67956622

Email:manager@cqhisea.com

Email:manager@cqhisea.com

Working Time: 9:00--17:00

Working Day: Monday to Friday Website: www.cqhisea.com

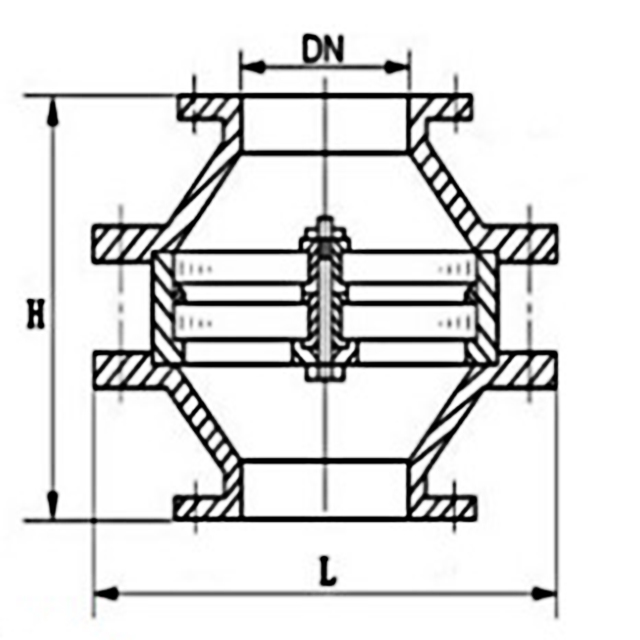

Explosion proof corrugated flame arresting for storage tank

Explosion proof corrugated flame arresting for storage tank

Description

Explosion proof corrugated flame arresting for storage tank prevents the external flame from entering the equipment containing flammable and explosive gases or prevents the flame from spreading between the equipment room. Explosion proof corrugated flame arresting for storage tank is designed and manufactured based on the principle that the flame passes through the narrow hole of the heat conductor and is extinguished due to heat loss. The fire barrier layer structure of Explosion proof corrugated flame arresting for storage tank has a gravel type, a wire mesh type or a corrugated type.

Explosion proof corrugated flame arresting for storage tank is one of the types of flame arresting used to prevent the flame from spreading from flammable gases and liquids and preventing tempering and causing an explosion. The fire-retardant layer in such a flame arresting is usually pressed by a stainless steel strip or a copper-nickel alloy material, and the size of the strip is determined by the nature of the gas and the flame speed. Regarding the working principle of the flame arresting, there are currently two main viewpoints: one is based on heat transfer; the other is based on the wall effect. Explosion proof corrugated flame arresting for storage tank is mainly composed of a casing and a fire-resistant plate. The casing should have sufficient strength to withstand the impact pressure generated by the explosion. Explosion proof corrugated flame arresting for storage tank can block the violent flame of detonation and can withstand the corresponding mechanical and thermal effects, with low flow resistance and easy to clean and replace. The ribbed flame retardant plate is supported by stainless steel, copper-nickel alloy, aluminum or aluminum alloy.

Specification

DN

Inch

Width (L/mm)

Height (H/mm)

25

1”

130

160

50

2”

200

175

80

3”

240

200

100

4”

280

210

125

5”

330

230

150

6”

370

250

200

8”

430

290

250

10”

480

320

DN

Inch

Width (L/mm)

Height (H/mm)

25

1”

130

160

50

2”

200

175

80

3”

240

200

100

4”

280

210

125

5”

330

230

150

6”

370

250

200

8”

430

290

250

10”

480

320

Model

ZHQ-1

Size

DN25-DN350 PN0.6-PN2.5

Body Material

CS 304 316 316L

Guide Rod

304 316 316L

Bolt /Nut

CS 304 316 316L

Gasket Seal

Graphite gasket

Medal gasket PTFE

Explosion Group

BS 5501:IIA IIB IIC

Ambient Temper

CS:-30℃~+350℃

SS:-80℃~+350℃

Joint Type

Flange Threaded

Flange Standard

JB GB HG ANSI SH JIS

Manufacture Standard

SY/T0511-1996

GB/T15908-86

Coating

CS: paint SS: NO Paint

Characteristics

The structure is reasonable, light weight, corrosion resistant, easy to repair and easy to install. The flame arresting core is made of stainless steel, which is corrosion resistant and easy to clean. The anti-explosion performance is qualified, and the 13 consecutive detonation performance tests can prevent fire at each time; the anti-firing performance is qualified, and the anti-firing test has no tempering phenomenon for 1 hour; the shell water pressure test is qualified.

Installation and Maintenance

In order to ensure the fire retarding effect of explosion proof corrugated flame arresting for storage tank, it should be checked every six months. Check the fire barrier for defects such as blockage, deformation or corrosion. The blocked fire-retardant layer should be cleaned to ensure that each hole is unobstructed, and the fire-resistant layer that is deformed or corroded should be replaced. When cleaning explosion proof corrugated flame arresting for storage tank core parts, it should be purged with high pressure steam, non-corrosive solvent or compressed air, and should not be brushed with sharp hardware. In order to facilitate on-site installation, our company has adjusted the fire-resistant core parts, which is not affected by the direction of the gas. The site can be directly installed on the required pipeline according to the flange standard. explosion proof corrugated flame arresting for storage tank is generally installed at a distance burning. The position of the furnace is about 5-10m, which can be installed horizontally or vertically; the pipeline installed by explosion proof corrugated flame arresting for storage tank must be clean, and there should be no impurities, dirt and other things blocking the gap of the fire-resistant core member, affecting the normal use of the flame arresting.

The fire-proof performance of explosion proof corrugated flame arresting for storage tank is regularly tested by 13 consecutive subsonic flame tests, which meets the requirements of national standards: explosion proof corrugated flame arresting for storage tank is protected from wear and tear on the flange sealing surface before leaving the factory, and the plastic protective cover for the import and export is supported. Be sure to remove the blue flange cover before installation on site:

When re-installing explosion proof corrugated flame arresting for storage tank, the gasket should be renewed and the sealing surface should be clean and free from damage and must not leak.

Order Notice

When ordering, please confirm the following parameters to provide you with the products that meet the requirements,

1, nominal diameter

2, working pressure

3, material

4, flange standard

5, medium