MARINE & OFFSHORE EQUIPMENT

- Dredging Equipment

- Marine Deck Machinery

-

Marine Mooring Equipment

-

Marine Anchor

- AC-14 HHP Anchor

- Admiralty Anchor

- Beldt Stockless Anchor

- Bruce Anchor

- Spek Anchor

- Danforth HHP Anchor

- Delta High Holding Power Anchor

- GB11579-89 Light Weight Anchor

- Hall Anchor

- High Holding Power Mastrosov Anchor

- Hot Dip Galvanized Anchor

- Japan Stock Anchor

- JIS Stockless Anchor

- Pool Anchor

- Single Fluke Anchor

- Stainless Steel Anchor

- Stevpris MK5 Anchor

- Stingray Anchor

- US Navy Stockless Anchor

-

Marine Anchor Chain

-

Marine Shackle

- Kenter Shackle

- D Type Joining Shackle

- Pear Shaped Shackle

- Anchor Swivel Shackle Type A

- Anchor Swivel Shackle Type B

- Buoy Shackle Type A

- Buoy Shackle Type B

- C Type Detachable Connecting Link

- D Shackle

- Forelock Shackle

- Anchor Chain Swivel Group

- Straight Shackle

- Anchor Shackle

- Marine Triangle Plate

- Anchor Chain Swivel

- Anchor Chain Joining Shackle

- Anchor Chain End Shackle

- Slim Kenter Shackle

-

Chain Chaser

-

Marine Bollard

-

Marine Chock

-

Marine Fairlead

-

Marine Chain Stopper

-

Marine Mooring Reel

-

Marine Towing Bracket

-

Mooring Rope

-

Marine Towing Hook

-

Marine Shark Jaw

- Marine Fender

-

Marine Buoy

- Marine Floating Pontoon Dock

-

Marine Anchor

- Aquaculture Equipment

- Marine Outfitting Equipment

- Marine Propulsion System

-

Marine Painting

-

Marine Auxiliary Machinery

- Marine Air Compressor

- Marine Air Receiver

- Marine Sewage Treatment Plant

-

Marine Diesel Generator Set

- Marine Oil Water Separator

- Ballast Water Management System

- Marine Hydrophore

- Marine Calorifier

- Seawater Desalination Plant

-

Marine Oil Separator

- Marine Fuel Oil Supply Unit

- Marine Heat Exchanger

-

Marine Hot Well Unit

-

Marine Incinerator

-

Marine Boiler

-

Marine Valve

- JIS Marine Valve

- DIN Marine Valve

- ANSI Marine Valve

- GB Marine Valve

- CB Marine Valve

- CBM Marine Valve

-

Marine Gate Valve

-

Marine Globe Valve

-

Marine Angle Globe Valve

-

Marine SDNR Valve

-

Marine Angle SDNR Valve

-

Marine Check Valve

-

Marine Storm Valve

-

Marine Butterfly Valve

-

Marine Quick Closing Valve

-

Marine Fire Valve

-

Marine Self Closing Valve

- Marine Valve Accessories

-

Marine Pump

- Marine Centrifugal Pump

- Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine External Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Domestic Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

- Marine Pump Parts

- Marine Life-saving Equipment

- Fire-fighting Equipment

- Marine Cable

- Marine Electrical Equipment

- Marine HVAC

-

Labour Protection Appliance

- Marine Decorative Material

-

Marine Anode

- Marine Pipe Fitting & Flange

- Marine Instrument

- Ship Building Equipment

INDUSTRY EQUIPMENT

- Hoisting Equipment

- Welding Machine & Material

-

Cutting Machine

- Container Securing Fitting

- Link Chain

- Container & Storage Equipment

-

Diesel Generator Set

- Other Equipment and Tools

- Petrochemical Equipment

- Fiber Reinforced Plastics

- Polymer Materials

- Environmental Protection Series

- Geo-products and Building Materials

- Metal Mesh

- Steel Grating

-

Earthwork Teeth

-

Turnbuckle

STOCK LIST

Contacts

Tel:+86-23-67956606

Tel:+86-23-67956606

FAX:+86-23-67956622

FAX:+86-23-67956622

Email:manager@cqhisea.com

Email:manager@cqhisea.com

Working Time: 9:00--17:00

Working Day: Monday to Friday Website: www.cqhisea.com

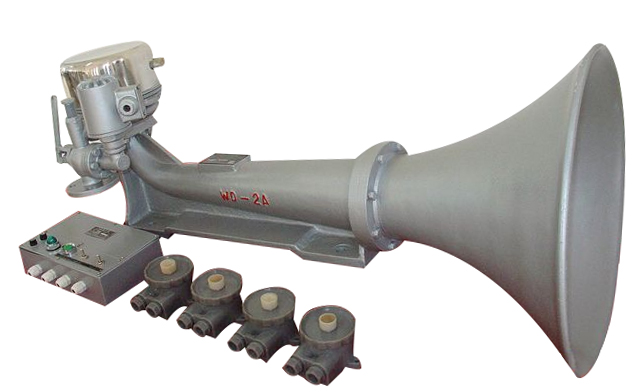

Marine Electric Horn

Marine Electric Horn

Description:

A marine electric air horn is a type of signaling device that produces a loud, distinctive sound for communication and warning purposes in marine applications. It is powered by electricity and typically consists of a compressor, a diaphragm or trumpet, and a control panel. The compressor is the heart of the system, which draws in air and compresses it before sending it to the diaphragm or trumpet. The diaphragm or trumpet amplifies the compressed air and produces the sound. The control panel allows the operator to activate and adjust the sound of the horn.

Marine electric air horns can be designed for various sound frequencies and output levels, and they typically have a longer service life than pneumatic or hand-operated air horns. They are also relatively easy to install and maintain. Marine electric air horns are commonly used on commercial and industrial vessels, as well as on pleasure boats, for signaling other boats or for use in emergency situations. They are often preferred over other types of air horns because they are more reliable and easier to operate.

Certificate: CCS

Standard:Rule 35, 36 of COLREG 1972 and SOLAS; IMO A. 1021(26) Resolution 2009 Alarm and Indicator Rules and 1972 the international maritime regulations for preventing collisions appendix 3 article 1 requirements, etc.

Application:

Suitable for vessels having length more than 75mts, and less than 200mts

Alerting other vessels: Marine electric air horns are used to signal to other boats and ships to communicate information such as maneuvering intentions or warnings of danger.

Navigation and collision avoidance: In congested waters, such as harbors or shipping lanes, marine electric air horns are used to signal to other vessels to avoid collisions.

Emergency situations: Marine electric air horns are also used in emergency situations, such as sounding a distress signal or calling for assistance.

Docking and mooring: Electric air horns can also be used to signal dock and mooring personnel to indicate the vessel's arrival or departure.

Marine electric air horns work on the principle of electromagnetism. The horn contains a diaphragm that vibrates when an electric current is passed through it. The diaphragm is made of a flexible material such as metal or plastic and is attached to an electromagnet. When the electric current flows through the coil, it creates a magnetic field that pulls the diaphragm towards it, causing it to vibrate and produce sound waves. The frequency and volume of the sound produced can be adjusted by changing the strength of the electric current or the tension on the diaphragm. The sound produced by marine electric air horns is typically loud and clear, making it an effective signaling device for communication in marine environments.

Product showcase:

|

Marine Electric Horn |

|||

|

|

|

|

|

|

|

|

|

|

Superiority & Innovation:

1. Industry innovation technology. The motor is used as the motive force, and the eccentric shaft is rotated at a high speed through gear transmission, which drives the piston to reciprocate at high speed in the piston cylinder to compress the air in the sound chamber to generate whistle.

2. Adopt microcomputer "MCU" control technology. Realizing man-machine dialogue, according to the actual needs of the ship, it can periodically and automatically send out "fog horn" signals with different coded information that meet the requirements of international conventions.

3. Integrate the air compressor, air storage tank and pipeline into one. Save raw materials; completely solve the problems in the use process such as gas tank leakage and pipeline blockage; save a lot of equipment installation space, making the ship design more reasonable and flexible

Picture of marine electric whistle:

.jpg)