MARINE & OFFSHORE EQUIPMENT

- Dredging Equipment

- Marine Deck Machinery

-

Marine Mooring Equipment

-

Marine Anchor

- AC-14 HHP Anchor

- Admiralty Anchor

- Beldt Stockless Anchor

- Bruce Anchor

- Spek Anchor

- Danforth HHP Anchor

- Delta High Holding Power Anchor

- GB11579-89 Light Weight Anchor

- Hall Anchor

- High Holding Power Mastrosov Anchor

- Hot Dip Galvanized Anchor

- Japan Stock Anchor

- JIS Stockless Anchor

- Pool Anchor

- Single Fluke Anchor

- Stainless Steel Anchor

- Stevpris MK5 Anchor

- Stingray Anchor

- US Navy Stockless Anchor

-

Marine Anchor Chain

-

Marine Shackle

- Kenter Shackle

- D Type Joining Shackle

- Pear Shaped Shackle

- Anchor Swivel Shackle Type A

- Anchor Swivel Shackle Type B

- Buoy Shackle Type A

- Buoy Shackle Type B

- C Type Detachable Connecting Link

- D Shackle

- Forelock Shackle

- Anchor Chain Swivel Group

- Straight Shackle

- Anchor Shackle

- Marine Triangle Plate

- Anchor Chain Swivel

- Anchor Chain Joining Shackle

- Anchor Chain End Shackle

- Slim Kenter Shackle

-

Chain Chaser

-

Marine Bollard

-

Marine Chock

-

Marine Fairlead

-

Marine Chain Stopper

-

Marine Mooring Reel

-

Marine Towing Bracket

-

Mooring Rope

-

Marine Towing Hook

-

Marine Shark Jaw

- Marine Fender

-

Marine Buoy

- Marine Floating Pontoon Dock

-

Marine Anchor

- Aquaculture Equipment

- Marine Outfitting Equipment

- Marine Propulsion System

-

Marine Painting

-

Marine Auxiliary Machinery

- Marine Air Compressor

- Marine Air Receiver

- Marine Sewage Treatment Plant

-

Marine Diesel Generator Set

- Marine Oil Water Separator

- Ballast Water Management System

- Marine Hydrophore

- Marine Calorifier

- Seawater Desalination Plant

-

Marine Oil Separator

- Marine Fuel Oil Supply Unit

- Marine Heat Exchanger

-

Marine Hot Well Unit

-

Marine Incinerator

-

Marine Boiler

-

Marine Valve

- JIS Marine Valve

- DIN Marine Valve

- ANSI Marine Valve

- GB Marine Valve

- CB Marine Valve

- CBM Marine Valve

-

Marine Gate Valve

-

Marine Globe Valve

-

Marine Angle Globe Valve

-

Marine SDNR Valve

-

Marine Angle SDNR Valve

-

Marine Check Valve

-

Marine Storm Valve

-

Marine Butterfly Valve

-

Marine Quick Closing Valve

-

Marine Fire Valve

-

Marine Self Closing Valve

- Marine Valve Accessories

-

Marine Pump

- Marine Centrifugal Pump

- Marine Screw Pump

-

Marine Gear Pump

-

Marine Vortex Pump

-

Marine Ejector Pump

-

Marine Diaphragm Pump

-

Marine Piston Pump

-

Marine Fire Pump

-

Marine Emergency Fire Pump

-

Marine External Fire Pump

-

Marine Ballast Water Pump

-

Marine Fuel Pump

-

Marine Lubricating Oil Pump

-

Marine Bilge Pump

-

Marine Sewage Pump

-

Marine Domestic Water Pump

-

Marine General Pump

-

Marine Cargo Oil Pump

-

Marine Hand Pump

- Marine Pump Parts

- Marine Life-saving Equipment

- Fire-fighting Equipment

- Marine Cable

- Marine Electrical Equipment

- Marine HVAC

-

Labour Protection Appliance

- Marine Decorative Material

-

Marine Anode

- Marine Pipe Fitting & Flange

- Marine Instrument

- Ship Building Equipment

INDUSTRY EQUIPMENT

- Hoisting Equipment

- Welding Machine & Material

-

Cutting Machine

- Container Securing Fitting

- Link Chain

- Container & Storage Equipment

-

Diesel Generator Set

- Other Equipment and Tools

- Petrochemical Equipment

- Fiber Reinforced Plastics

- Polymer Materials

- Environmental Protection Series

- Geo-products and Building Materials

- Metal Mesh

- Steel Grating

-

Earthwork Teeth

-

Turnbuckle

STOCK LIST

Contacts

Tel:+86-23-67956606

Tel:+86-23-67956606

FAX:+86-23-67956622

FAX:+86-23-67956622

Email:manager@cqhisea.com

Email:manager@cqhisea.com

Working Time: 9:00--17:00

Working Day: Monday to Friday Website: www.cqhisea.com

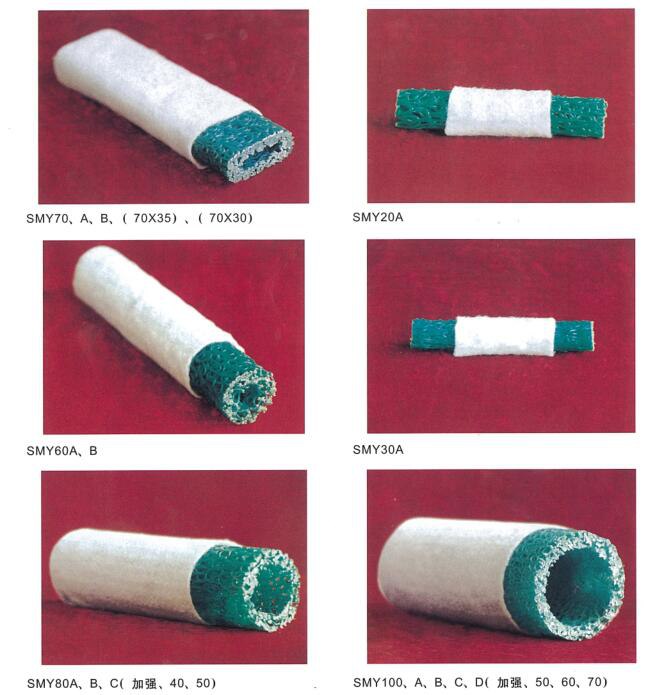

Plastic Water-Permeable Blind Drain Ditch

Plastic Water-Permeable Blind Drain Ditch

Specifications and Parameters Indicators

|

Model |

Rectangle Cross Section Series |

Round Cross Section Series |

||||||||

|

MF0730 |

MF1435 |

MF1550 |

MF1235 |

MY60 |

MY80 |

MY100 |

MY150 |

MY200 |

||

|

Outer Size Width×Thickness(≥mm) |

70*30 |

140*35 |

150*50 |

120*35 |

φ60 |

φ80 |

φ100 |

φ150 |

φ200 |

|

|

Hollow Size Width×Thickness(≥mm) |

40*10 |

40*10*2 |

40*20*2 |

40*10*2 |

φ25 |

φ45 |

φ55 |

φ80 |

φ120 |

|

|

Weight(≥g/m) |

350 |

650 |

750 |

600 |

400 |

750 |

1000 |

1800 |

2900 |

|

|

Porosity(%) |

82 |

82 |

85 |

82 |

82 |

82 |

84 |

85 |

85 |

|

|

Compression Strength KPa |

Flatness Ratio5%≥ |

60 |

80 |

50 |

70 |

80 |

85 |

80 |

40 |

50 |

|

Flatness Ratio10%≥ |

110 |

120 |

70 |

110 |

160 |

170 |

140 |

75 |

70 |

|

|

Flatness Ratio15%≥ |

150 |

160 |

125 |

130 |

200 |

220 |

180 |

100 |

90 |

|

|

Flatness Ratio20%≥ |

190 |

190 |

160 |

180 |

250 |

280 |

220 |

125 |

120 |

|

Note:

1. Other cross section patterns, sizes or technical spec. are available. Please contact us to customize.

2. Coating Filter cloth: 90g/m2 filament woven geotextiles or 100-300g/m2 knitted geotextiles. All geotextiles meet Chinese Industrial Standard.

Other Models of Plastic Water-Permeable Blind Channel

Construction Guidelines

Plastic Water-Permeable blind ditch filter products are available in a variety of synthetic fiber filters. Fiber non-woven filter (70-400g/m2) is the most common. It depends on the soil properties and water inflow of the site.

Generally speaking, for ordinary soil, 150g/m2 filter membrane is more suited, and for the part with large water immersion is advised to fully pave with gravel instead of filter membrane. In case there is no gravel to be backfilled but original soil, please expose them in the sun for 2-3 days(except sticky soil) before backfill.

The judgment of the selected filter is as follows: When there is concern that the water is less, and the water containing the fine particles (inflow through the filter membrane) is accumulated for a long time, the synthetic fiber non-woven thin type filter is recommended, because it can help the water continuously discharged with fine soil.

If gravel is adequately laid in a place where there is a large amount of water in the gravel soil, the filter could be omitted. The filter has two original rolls of 100 meters and two kinds of bag-shaped joining types of sizes 2m-8m.

Roll series feature for fast construction, but difficult to bury it in narrow deep trench. Bag-shaped joint series (wrapped) are suggested for small diameter plastic blind groove materials. When using the roll filter, first put a filter film in the trench and then place the plastic blind groove material, and use the filter film to wrap the plastic blind groove material from the left and right direction. The joint of the plastic blind groove material should be nailed with two special fitting claw-nails and then backfilled. For the cross seam, prepare a non-woven fabric or a suitable vinyl film to entangle the intersection. The final part of the plastic blind ditch should be connected to the rest (plastic or cement outlet pipe), and the joint should be coated with mortar to prevent the culvert water from discharging the sand. If the water contains precipitable substances, it is best to use a nylon mesh with different meshes as a filter to prevent the sediment from gradually clogging in the outer layer of the filter, so that the drainage function is lost.