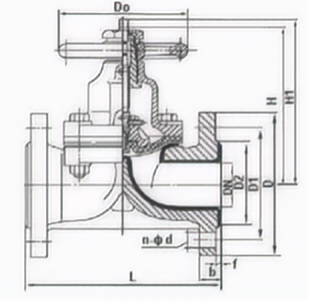

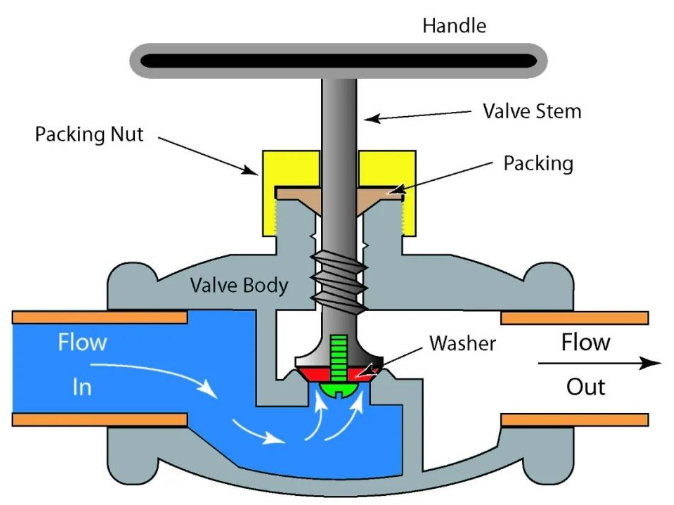

l Globe valves are very suitable for cutting off or adjusting and throttling. Because the opening or closing stroke of the valve stem is relatively short, and it has a very reliable cut-off function, and because the change of the valve seat port is in direct proportion to the stroke of the disc, it is very suitable for flow regulation.

l The globe valve is designed to be low in and high out, so as to make the flow resistance small and save effort when opening the valve. At the same time, when the valve is closed, the packing between the valve shell and the valve cover and the packing around the valve stem are not stressed, which will not be affected by the pressure and temperature of the medium for a long time, thus prolonging the service life and reducing the probability of leakage. In addition, the packing can be replaced or added when the valve is closed, which is convenient for maintenance.

Special circumstances cut-off valve is low out high in:

① Boiler exhaust globe valve

② The diameter is greater than 100mm of high pressure globe valve.

③ Two globe valves connected in series on the bypass pipeline, and the second globe valve requires "low out and high in".

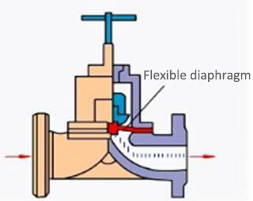

Installation and maintenance of diaphragm valve

l Before the diaphragm valve is installed, carefully check whether the operating conditions of the pipeline are consistent with the scope of use specified in this valve, and clean the inner cavity to prevent dirt from blocking or damaging the sealing parts.

l Do not brush grease on the rubber lining layer and rubber diaphragm surface to prevent rubber swelling and affect the service life of diaphragm valve.

l The hand-wheel or transmission mechanism, are not allowed to be used for lifting, and collision is strictly prohibited.

l When manually operating the diaphragm valve, the auxiliary lever is not allowed to be used to prevent excessive torque from damaging the driving parts or sealing parts.

l Diaphragm valves should be stored in a dry and ventilated room, and stacking is strictly prohibited.

l The channels at both ends of the stored diaphragm valves must be sealed, and the opening and closing parts should be in a slightly open state.

|

|

|

|